Application examples

Identify substances and determine concentrations

Optoquant offers you innovative and powerful measurement solutions across all technologies for all industrial sectors.

Would you like to know whether your measurement task can also be solved with Optoquant technologies? Contact us!

Increasing efficiency around the clock

...in the laboratory

...and in production!

We offer analysis methods for gases, liquids and solids, both for laboratory operation and for production (24/7). Even in explosion-proof environments!

Our products and services are already helping a large number of users to optimize their processes. The areas of application are diverse and range from chemicals/petrochemicals, renewable energies and semiconductor technology to biotechnology, pharmaceuticals, food production and mining.

Optoquant technology is a powerful, versatile and flexible analysis tool for process monitoring - particularly in individual production steps such as thermal separation processes (distillation, rectification), mechanical separation processes (filtration, sedimentation, centrifugation), extraction and sorption of gases and vapors.

Would you like to find out more about the wide range of possible applications? On this page you will find an overview and an insight into exemplary sensor applications. Your application is not listed? Contact us!

The following is just a small selection of possible applications in the process and laboratory:

- Production of basic and fine chemicals

- Monitoring of mixing processes

- Detection of contaminants in solvents

- Pharmaceutical production, e.g. active pharmaceutical ingredients (APIs)

- Tablet dissolution tests, active ingredient release

- Quality control in the cosmetics industry

- Gas analysis, e.g. natural gas analysis, hydrogen and much more

- Fertilizer production

- Fermentation monitoring

- Petrochemistry

- Gasoline production

- Food analysis

- Caffeine analysis

- Edible oil analyses

- Polymer processes, polymer formation monitoring

- Polystyrenes

- Polyurethanes

- Process monitoring, reaction analysis

- All scales - from microreactors to large-scale production

- Rock analysis

- Semiconductor analytics

- and much more...

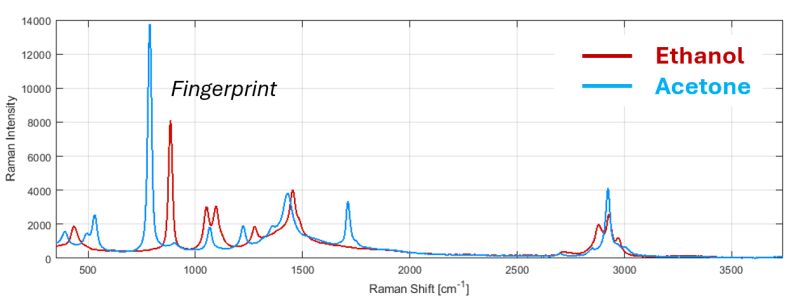

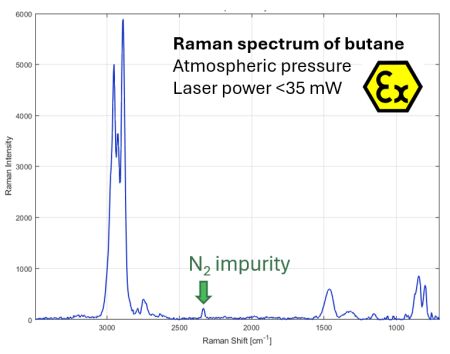

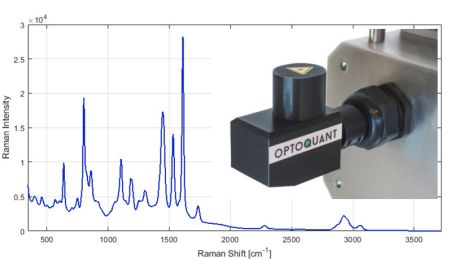

Raman spectroscopy is a spectroscopic analysis method that can be used to identify substances and determine concentrations. The sample to be analyzed is irradiated with a laser. A very small proportion of the light interacts at the molecular level - the so-called Raman scattering. This light is optically separated according to “color” and detected. A Raman spectrum is obtained by plotting the measured intensities of each color.

The spectrum obtained in this way contains a fingerprint area in which substances leave their characteristic “fingerprint”. The intensity is also a measure of the respective concentration of a substance. Raman spectroscopy is therefore a powerful tool both in the laboratory and in process analysis technology (PAT). The method is suitable for gases, liquids and solids.

Inline monitoring in the BASF lab

Future-proof through innovation and sustainability

The Optoquant Raman sensor is in use around the clock (24/7) at BASF's kinetics laboratory in Ludwigshafen, providing real-time data on chemical processes within minutes. Direct, continuous measurement eliminates time-consuming laboratory analyses and hazardous sampling, significantly increasing occupational safety and throughput.

The compact design and easy integration of the sensors enable flexible use in existing plants, while the self-sufficient systems require little installation effort. BASF thus benefits from immediate information about catalysts and process parameters, saves costs and resources, and promotes sustainable production methods.

The successful implementation in the laboratory shows how innovative process analytics paves the way for effective and reliable work in industry. Find out how Optoquant technology creates decisive advantages – in the complete success story:

Degree of hydrogenation

Monitoring the degree of hydrogenation of liquid organic hydrogen carriers

Liquid organic hydrogen carriers (LOHC) are organic substances that can be loaded and unloaded with hydrogen through a catalyzed reaction. This technology can be used to store and transport sustainable hydrogen safely, efficiently and economically. With the Optoquant Raman sensor, a solution has been developed to determine the degree of hydrogenation (degree of hydrogen loading) easily and with high accuracy. Thanks to the device's internal evaluation, the system can determine the hydrogen load as LOHC Degree of hydrogenation in real time and output it via the process interface.

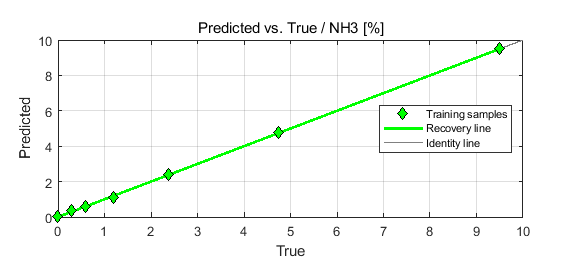

Ammonia sensor

Monitoring the ammonia concentration in aqueous solution

Ammonia is one of the most frequently produced basic chemicals, the starting material for the production of all other nitrogen compounds and also a critical environmental pollutant. Reliable analysis for the determination of ammonia is therefore of great importance both for industrial production and for environmental monitoring. With the Optoquant Raman sensor, ammonia dissolved in liquids can be detected and precisely quantified at concentrations < 0.5 % with a laser power of just 0.7 mW. The figure shows the calibration of the sensor to the ammonia concentration in aqueous solution based on a characteristic Raman band at 3300 cm-1. The use of the pre-calibrated system as an Ammonia sensor enables Raman-based inline measurement in product-carrying pipes without the complex and costly installation effort of an invasive measuring point.

Gas analyzer

Inline analysis of gases in explosion-proof areas

In modern production, process information is a decisive market advantage for increasing efficiency. Our Optoquop Process Raman spectrometer for gases enables you to monitor the gas composition “inline” and in real time. Detect changes in the composition of the atmosphere to be analyzed or the gas flow in explosion-protected areas. The laser may shine into Zone 0 and has a temperature class T4. The spectrometer may be set up in Zone 1.

Increase the efficiency of your production processes with the Optoquop process and become more profitable and more resistant to external market influences.

- Continuous process optimization through knowledge of the chemical composition

- Quick and easy detection of the gas composition -

detect anomalies as they arise and avoid expensive faulty batches - Extremely wide range of applications - even small molecules are often ramanactive (oxygen, nitrogen, hydrogen, etc.)

NCO sensor

Know your process status at all times, reduce waste and save chemicals and working time!

Polyurethanes (PUR) are important plastics for almost all industrial sectors. PUR can be found in a number of products: from construction foam to mattresses, casting compounds, packaging, car parts and footballs. The possibilities are almost unlimited.

The wide range of possible applications and properties are defined and determined directly in the manufacturing process. Only optimum conditions during the manufacturing process lead to the respective product with its specific properties. The determination of the free isocyanate concentration (NCO content) plays a key role here. The labor-intensive laboratory method of titration has established itself as the standard method for analysis. This results in comparatively high ongoing personnel and chemical costs. As the required values are only available with a time delay, problems in production cannot be detected immediately. Translated with DeepL.com (free version)

Optoquant technology provides a remedy here - both in the laboratory and directly in the process. Measure quickly and easily in a glass vial or directly inline in production. The analysis time is reduced to just a few minutes, eliminating time-consuming sample preparation and long measuring times.

Have we aroused your curiosity? Please contact us and we will optimize your process together.